F104 Epoxy Composite Adhesive Can Resist Aging Good Compressive Performance

1. Descriptions:

F104 is a two-component adhesive. Component A is composed of epoxy resin, toughening agent and filler, and the appearance is white viscous fluid. Component B is a modified polyamide curing agent, which is composed of accelerator and coupling agent, and is a yellow micro thixotropic fluid.

This product is easy to use, suitable for scraping in all directions and easy to operate. After curing, it has high bonding strength, hard rubber block, good compressive performance, no shrinkage during curing, corrosion resistance and aging resistance.

2. Specifications:

| Epoxy Adhesive 104 |

| Component A |

Off white fluid |

| Component B |

Light beige liquid |

| A: Density (g/cm3) |

1.55 |

| B: Density (g/cm3) |

1.37 |

| A: State |

Fluid |

| B: State |

Liquid |

| Shearing Strength |

≥15MPa |

| Mixing ratio |

2:1 |

| Initialadhesive formation |

6-8 hours |

| Rollerpeel strength |

≥50 (N.mm)/mm |

| Features |

Good adhesive, high strength, certain toughness, temperature resistance, water resistance, water resistance, not swelled to the HPL board, can be used indoor and outdoors |

3. Epoxy Adhesive has several advantages:

• High cost performance

• High strength

• Water and high temperature resistant

4. Applications:

• This product is mainly used for bonding and hanging the indoor stone, like directly bonding and hanging the marble & granite etc on the indoor wall or on the concrete wall with metal, also can be used for bonding the different materials like stone, metal, concrete, cement block, clay brick etc.

• Used for bonding oneself and mutual of metal, ceramic and foamed PVC board etc. where high impact strength and peeling strength resistance are required, such as train, shipbuilding, automobile engine assembly.

• Also it can be used for bonding of various composite material structural parts.

5. Quality control:

A very technical engineering team. The general manager has worked in the Netherlands. The core technologies are introduced from the Netherlands. Others are very young and have more than 5 years of practical experience.

Strict QC team: 8 people are responsible for epoxy adhesive of quality control of parts, processing, testing, packaging, etc.

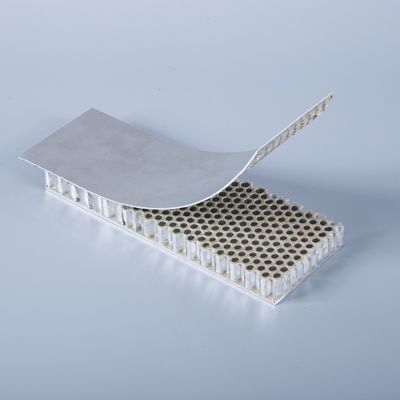

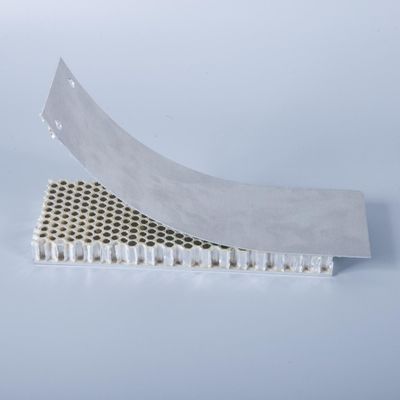

6. Epoxy Adhesive of more pictures:

7. Company profile

Suzhou Beecore Honeycomb Materials Co.Ltd, originated from Besin (Dutch) International Group which was founded in 1957. It is the world's leading professional manufacturer of honeycomb materials. Since it' s established, the company has been committed to the research and development of honeycomb technology, from slant-porous aluminum honeycomb core, honeycomb core, honeycomb panel, to the finished product which was using honeycomb panel as the solution, such as truck body, laser TV / projection screen etc. , We always stick to the roots of continuous technological innovation, and constantly upgrade and expand the application of the honeycomb materials, becoming the first choice company for solutions of honeycomb materials.

At present, we hold more than 60% market share in the Yangtze River Delta of China. The overseas market covers Europe, America, Middle East, Southeast Asia and other countries, praised by domestic and foreign customers.

8. History

1957 Besin(Dutch)1International Group was established and dedicated to research and development of BEECORE and BEEBOARD.

1958 Besin brought honeycomb technology into China, and Besin (Suzhou) company was established.

2002 Beecore (Guangdong) factory was established and have 10 aluminum honeycomb production lines.

2009 Suzhou Beecore Honeycomb Materials Co., Ltd was established and mainly produce aluminum honeycomb core and paper honeycomb core and other products.

2010 Beecore products are widely used for railway industry, Shanghai Expo, marine furniture etc.

2014 Beecore developed micro-porous aluminum honeycomb core and slant-porous aluminum honeycomb core, PU adhesive, as well as honeycomb filters.

2015 Beecore added honeycomb panels production lines, specialized in super length, width, curved, and special honeycomb panels of industry field.

2016 The self-developed aluminum honeycomb equipment has been exported to Europe, America, Asia and already obtained the technology patent in China.

2017- so far Suzhou Beecore Honeycomb Materials Co., Ltd is honored as the high-technology innovation enterprise.

9. Matters needing attention:

1. The amount of glue should not be too much to avoid accelerating curing and shortening the application period due to exothermic reaction.

2. There shall be absolutely no water during bonding. Roughening the bonded surface can increase the bonding strength, while epoxy primer on the bonded metal surface can increase the bonding strength.

The surface to be bonded and coated after pretreatment shall be dry and free of grease, dust or other dirt. If the metal surface is coated with primer or the plastic surface has discharge agent, it shall be removed; The bonded surface is polished. In some special cases, epoxy primer or anodic oxidation may be used, and the adhesion will increase significantly.

Construction and bonding F104 take an appropriate amount of glue solution respectively according to the mass ratio a: B = 2:1 and mix evenly (take a and B

The color of the two glue solutions shall be mixed evenly as the judgment basis), and then the evenly stirred colloid shall be coated, scraped and troweled on the required plate with a scraper, with the sizing amount of 0.35-0.5kg per square meter.

After mixing, F104 can be mixed evenly at room temperature for about 50 ~ 60 minutes, and the initial curing time at 25 ℃ is about 6 ~ 7 hours. If the temperature is low, the curing time needs to be prolonged. It can also be cured quickly by heating. Generally, it can be basically cured after 1 hour at 60 ℃.

The uncured glue can be cleaned with special cleaning agent, such as acetone. The cured glue can only be removed by mechanical method.

Preservation:

Afraid of freezing: Yes

Storage temperature: at room temperature (recommendation: about 25 ℃), when the storage temperature is too high, the reaction speed is fast and the operation time is short after taking and mixing; The temperature is too low, the viscosity is thickened, and the glue mixing and scraping are laborious.

Validity: 12 months after the original packaging

Packing:

Barrel packing: 2 barrels of 25kg (component a), and 25kg (component B) can also be packed according to the specific requirements of customers

10. FAQ

Q1. What is epoxy adhesive used for?

A: Epoxy composite adhesives are widely used in the construction industry, automobile manufacturing and shipbuilding, such as polyurethane sandwich panels, aluminum honeycomb panels, polystyrene foam panels, fiberglass panels, stone composite panels, metal plates, etc.

Q2. What are the advantages of Epoxy adhesive?

A: Epoxy adhesive has the advantages of good flexibility, high bonding strength, cost-effective, water and heat resistant

Q3. What is the packaging method of Epoxy adhesive?

A: Epoxy adhesive of samples are packed in cardboard and bulk orders are packed in plywood cases.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!