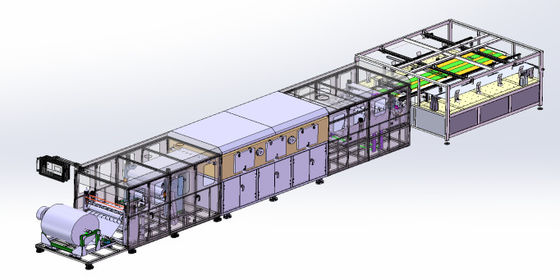

INTRODUCTION

General layout of A600 adhesive line

This device is a specialized equipment mainly used for coating, cutting, and stacking aluminum honeycomb cores. It can coat, dry, and cut aluminum foil to a fixed length.

a. Process Description:

According to the needs, the required aluminum coils are unrolled and coated with special adhesive for aluminum honeycomb core for gravure printing. After drying in an oven, they are punched and flattened according to the process requirements, and then cut and stacked to a fixed length.

b. Equipment Features

The aluminum honeycomb coating machine designed and manufactured by our company has the following main features:

1) Automatic constant tension control for unwinding coil tension;

2) The floating roller can automatically adjust the synchronization function of the production line;

3) After gluing, it can automatically dry; Accurate temperature control in the oven

4) The coated material can automatically drill holes

5) Single board testing can automatically measure the strip spacing and calculate the pitch of the adhesive strip for different models of plate rollers after coating.

6) After gluing, the automatic and accurate fixed length cutting can achieve the positioning of the aluminum foil near the end after gluing.

A.Loading and gluing unit

This unit includes functions such as aluminum foil feeding, aluminum foil traction, aluminum foil puncture hole, aluminum foil flattening, aluminum foil synchronization, and aluminum foil gluing.

Detailed parameters of the correction system

| Correcting brand |

Option A |

Option B |

Option C |

| Correction accuracy |

±0.5mm |

±0.5mm |

±0.3mm |

| motor speed |

115 rpm /min |

115 rpm /min |

350 rpm /min |

| Actuator thrust |

100KG |

100KG |

100KG |

| Execution mechanism load |

1T |

1T |

1T |

| Execution mechanism itinerary |

140mm |

140mm |

140mm |

| Execution mechanism speed |

10±10%mm/min

|

10±10%mm/min

|

1mm/s-75mm/s Adjustable |

| Drive mode |

Synchronous motor |

Synchronous motor |

servo |

B.Automatic gluing unit

The automatic glue adding equipment consists of a mixing tank, ultrasonic probe, pneumatic motor mixer, and main engine box (the main engine box consists of three parts: upper, middle, and lower parts, with the upper part being the high-level tank solvent tank, the middle part being the main control electrical box and human-machine operation interface, and the lower part being the pneumatic diaphragm pump)

C.Tunnel type constant temperature unit

Number of temperature control points: 4

Working temperature: 0~120 ° C (maximum furnace temperature of 150 ° C)

Alarm protection for overheating, disconnection, overload, etc

Heating power: 20KW

Temperature control accuracy: 3-5 ℃

D.Cooling cutting unit

E.Fully automatic dual station aluminum honeycomb core automatic laminating machine

1) Suitable for aluminum foil width: 580-600mm.

2) Stacking length: 900-1800mm.

3) Maximum speed: 25PCS/min (calculated using 1700mm long aluminum foil).

4) Maximum stacking height: 200mm.

5) When the number of single-sided sheets reaches the set number, the direction will automatically switch.

6) The position of the suction cup can be adjusted in the front, back, left, and right directions.

7) The equipment is equipped with foot screws that can be adjusted horizontally.

8) The height of the feeding port can be adjusted: 1050-1150mm.

9) Stacking trolley height: 700mm.

F.Equipment List

| NO. |

NAME |

NUMBER |

UNIT |

Manufacturer |

|

| 1 |

Aluminum foil tensioning system |

1 |

SET |

BEECORE |

|

| 2 |

Aluminum foil puncture system |

1 |

SET |

BEECORE |

|

| 3 |

Aluminum foil coating system |

1 |

SET |

BEECORE |

|

| 4 |

Drying system |

1 |

SET |

BEECORE |

|

| 5 |

Aluminum foil buffer system |

1 |

SET |

BEECORE |

|

| 6 |

Aluminum foil cutting system |

1 |

SET |

BEECORE |

|

| 7 |

Control system |

1 |

SET |

BEECORE |

|

List of main accessories:

| NO |

NAME |

NUMBER |

UNIT |

Manufacturer |

|

| 1 |

Frame |

1 |

SET |

BEECORE |

|

| 2 |

Oven |

1 |

SET |

BEECORE |

|

| 3 |

Roller shaft |

39 |

SET |

co-partner |

|

| 4 |

Machined parts |

|

SET |

co-partner |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!