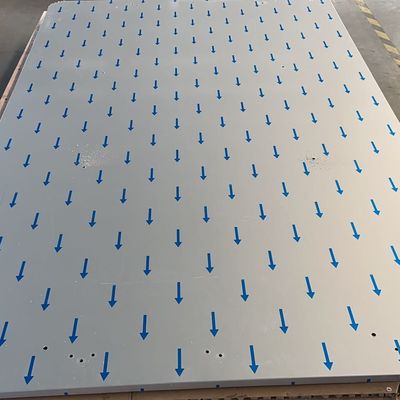

Customizable Aluminum Honeycomb Panel Honeycomb Sandwich Panel For Top Tent Car

Product Description:

Aluminum Honeycomb Panels are a lightweight and cost-effective alternative to solid aluminum panels, featuring honeycomb structures with aluminum panels. The maximum size of these panels is 2400mm X 1200mm, providing plenty of space to work with. These panels also have a fireproof grade of B1, making them suitable for a variety of applications. Additionally, Aluminum Honeycomb Panels boast a flatness of ≤0.5mm, ensuring that they remain stable and sturdy. Furthermore, these panels have an impact resistance of ≥20KJ/m2, meaning that they can withstand the pressure of everyday wear and tear.

Features:

Rigidity and stability: The honeycomb structure of aluminum panels enhances their rigidity and stability. The hexagonal cells distribute the load evenly across the panel, minimizing deformation and improving overall structural integrity. This rigidity makes them resistant to bending, warping, and vibrations, ensuring long-term performance and durability.

Thermal and acoustic insulation: Aluminum honeycomb panels offer effective thermal and acoustic insulation properties. The air-filled cells within the honeycomb structure act as insulating chambers, reducing heat transfer and sound transmission. This makes them useful for applications requiring temperature control, noise reduction, and acoustic isolation, such as cleanrooms, theaters, and soundproof enclosures.

Corrosion resistance: Aluminum is inherently resistant to corrosion, and this property extends to aluminum honeycomb panels. They can withstand exposure to moisture, chemicals, and harsh environmental conditions without deteriorating or rusting. This corrosion resistance makes them suitable for outdoor applications, including building exteriors and marine environments.

Versatility in design and customization: Aluminum honeycomb panels offer design flexibility and customization options. They can be easily cut, shaped, and formed into various sizes and configurations, allowing for creative and intricate designs. They are available in different surface finishes, colors, and textures, enabling architects and designers to achieve their desired aesthetic effects.

Technical Parameters:

| Parameter |

Value |

| Material |

Aluminum |

| Product name |

Aluminum honeycomb panels |

| Honeycomb Cell Size |

3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 10mm, Etc. |

| Surface Treatment |

Anodizing, Powder Coating, PVDF Coating |

| Sound Insulation |

Good |

| Application |

Furniture, Building Curtain Wall |

| Thickness |

5mm-100mm |

| Features |

Light weight , high strength |

| Color |

Silver, White, Black, Etc. |

| Heat Insulation |

>=0.05m2K/W |

Applications:

Aluminum Honeycomb Panels are a lightweight and durable structural panel. They are made of aluminum honeycomb core sandwiched between two layers of aluminum structures, ensuring superior strength and stability. These panels are perfect for building curtain wall applications, and come in a variety of colors, such as silver, white, and black. They are available in thicknesses ranging from 5mm to 100mm, and can provide up to 5.5kg/m2 of weight when fully installed. Not only are they lightweight, but aluminum honeycomb panels are also highly durable, making them an ideal choice for long-term structural applications.

Packing and Shipping:

FAQ:

- Q: What is an Aluminum Honeycomb Panel?

A: An Aluminum Honeycomb Panel is a lightweight, high-strength composite panel made up of two aluminum sheets bonded to a honeycomb core.

- Q: How is an Aluminum Honeycomb Panel used?

A: Aluminum Honeycomb Panels are widely used in a variety of industries and applications, including aerospace, automotive, defense, and marine.

- Q: What are the benefits of Aluminum Honeycomb Panels?

A: Aluminum Honeycomb Panels provide superior strength-to-weight ratio, excellent stiffness, and superior impact and vibration resistance. They are also corrosion-resistant, fireproof, and environmentally sustainable.

- Q: What sizes are available for Aluminum Honeycomb Panels?

A: Aluminum Honeycomb Panels are available in a variety of sizes and shapes, and can be customized to meet specific customer needs.

- Q: What finishes are available for Aluminum Honeycomb Panels?

A: Aluminum Honeycomb Panels are available in a variety of finishes, including anodized, painted, and powder coated.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!