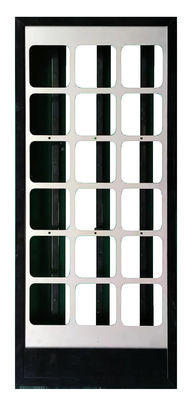

High Efficiency And Low Resistance Micro Electrostatic Filter Screen

1. Descriptions:

Micro static electricity is a new generation of purification technology, which is created through thorough innovation of materials and structures. It is a green, energy-saving, weather resistant, high-efficiency, low resistance, high dust tolerance, and electronic purification and disinfection technology that can be used in harsh and complex environments.

The charging electrode of a micro electrostatic air filter ionizes the air in the channel into ionized particles through glow discharge, which charges the passing fine particles; The dust collection electrode plate adopts a conductive non dielectric polymer new material electrode film as the carrier; The electrode membrane is divided into high potential group and low potential group. The filter adsorbs moving particles in the air through the strong electric field generated between the electrode membranes of the high and low potential groups. At the same time, bacteria and other microorganisms attached to the particles are synchronously collected and killed in the strong electric field

2. Specifications:

| Micro Electrostatic Filter Screen |

| Product name |

Micro Electrostatic Filter Screen |

| Carrier |

Dielectric free polymer new material electrode film |

| Size |

580*254mm ,780*254mm or Customizable |

| Rated air volume |

680 m3/h |

| Consumption |

5w |

| Windage |

3-7-10Pa |

| Thickness |

90mm |

| Filtering efficiency |

> |

3. Micro Electrostatic Filter Screen has several advantages:

Efficient purification: Up to 99% one-time purification efficiency for PM2.5

Disinfection and sterilization: block bacteria, with a fire extinguishing rate of up to 99% against viruses

Low carbon and environmental protection: saving energy up to 5000 kWh/year/10000 wind capacity

Near zero maintenance cost: Design lifespan>15 years, during which only cleaning and no replacement are required

Micro Electrostatic Filter Core advantages:

Large dust capacity: The dust capacity far exceeds that of HEPA filters and micro electrostatic filters.

Anti leakage: The positive and negative plates of the power supply point are completely isolated, and there is no discharge leakage.

Strong adaptation: operates in harsh environments while maintaining high efficiency.

Low resistance: Under wind speed conditions, the resistance is small, and there is no significant increase in resistance during long-term operation

4. Applications of Micro Electrostatic Filter Screen:

• Fresh air system, air purifier, air conditioner, Box type air conditioning, various pipelines

5. Quality control:

A very technical engineering team. The general manager has worked in the Netherlands. The core technologies are introduced from the Netherlands. Others are very young and have more than 5 years of practical experience.

Strict QC team: 8 people are responsible for aluminum honeycomb core photocatalyst filter of quality control of parts, processing, testing, packaging, etc.

6. Aluminum Honeycomb Core Photocatalyst Filter of more pictures:

7. Company profile

Suzhou Beecore Honeycomb Materials Co.Ltd, originated from Besin (Dutch) International Group which was founded in 1957. It is the world's leading professional manufacturer of honeycomb materials. Since it' s established, the company has been committed to the research and development of honeycomb technology, from slant-porous aluminum honeycomb core, honeycomb core, honeycomb panel, to the finished product which was using honeycomb panel as the solution, such as truck body, laser TV / projection screen etc.

8. History

1957 Besin (Dutch) International Group was established and dedicated to research and development of BEECORE and BEEBOARD.

1958 Besin brought honeycomb technology into China, and Besin (Suzhou) company was established.

2002 Beecore (Guangdong) factory was established and have 10 aluminum honeycomb production lines.

2009 Suzhou Beecore Honeycomb Materials Co., Ltd was established and mainly produce aluminum honeycomb core and paper honeycomb core and other products.

2010 Beecore products are widely used for railway industry, Shanghai Expo, marine furniture etc.

2014 Beecore developed micro-porous aluminum honeycomb core and slant-porous aluminum honeycomb core, as well as honeycomb filters.

2015 Beecore added honeycomb panels production lines, specialized in super length, width, curved, and special honeycomb panels of industry field.

2016 The self-developed aluminum honeycomb equipment has been exported to Europe, America, Asia and already obtained the technology patent in China.

2017- so far Suzhou Beecore Honeycomb Materials Co., Ltd is honored as the high-technology innovation enterprise.

9. Factory show

10. FAQ

Q1. What is Micro Electrostatic Filter Screen usd for?

A: The Micro electrostatic filter is suitable for various types of ventilation ducts.

Q2. What are the advantages of Micro Electrostatic Filter Screen?

A:

1. Efficient purification: Up to 99% one-time purification efficiency for PM2.5.

2. Disinfection and sterilization: block bacteria, with a fire extinguishing rate of up to 99% against viruses.

3. Low carbon and environmental protection: saving energy up to 5000 kWh/year/10000 wind capacity.

4. Near zero maintenance cost: Design lifespan>15 years, during which only cleaning and no replacement are required.

Q3. What is the packaging method of Micro Electrostatic Filter Screen?

A: Micro electrostatic filter of samples are packed in cardboard and bulk orders are packed in plywood cases.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!