Bending And Edge Sealing Aluminu Honeycomb Panels Aluminum Honeycomb Sandwich Panel

Product Description:

Aluminum Honeycomb Panels are a kind of honeycomb composites, which are made of aluminum honeycomb structures. The core structure of the panel is aluminum honeycomb, which is lightweight, high strength and good rigidity. The product name is Aluminum Honeycomb Panels, with fireproof grade B1, and durability of more than 10 years. The surface treatment of the panels includes anodizing, powder coating and PVDF coating, which can meet the requirements of various environment.

Aluminum Honeycomb Panels are characterized by high strength, good rigidity, light weight, fireproof grade B1, durability of more than 10 years, and surface treatment of anodizing, powder coating and PVDF coating. It is widely used in construction, transportation, aerospace, military and other industries.

Features:

High strength-to-weight ratio: Despite their lightweight nature, aluminum honeycomb panels exhibit high strength-to-weight ratio. The honeycomb structure provides excellent load-bearing capabilities, making them strong and rigid. This property makes them suitable for applications that require structural strength, such as building facades, cladding, and flooring.

Rigidity and stability: The honeycomb structure of aluminum panels enhances their rigidity and stability. The hexagonal cells distribute the load evenly across the panel, minimizing deformation and improving overall structural integrity. This rigidity makes them resistant to bending, warping, and vibrations, ensuring long-term performance and durability.

Thermal and acoustic insulation: Aluminum honeycomb panels offer effective thermal and acoustic insulation properties. The air-filled cells within the honeycomb structure act as insulating chambers, reducing heat transfer and sound transmission. This makes them useful for applications requiring temperature control, noise reduction, and acoustic isolation, such as cleanrooms, theaters, and soundproof enclosures.

Technical Parameters:

| Product Name |

Technical Parameters |

| Aluminum Honeycomb Panels |

Weight: 4-5.5kg/m2

Heat Insulation: ≥0.05m2K/W

Application: Building Curtain Wall

Thickness: 5mm-100mm

Honeycomb Cell Size: 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 10mm, Etc.

Core Structure: Aluminum Honeycomb

Surface Treatment: Anodizing, Powder Coating, PVDF Coating

Flatness: ≤0.5mm

Max Size: 2400mm X 1200mm |

Applications:

Aluminum Honeycomb Panels have been widely used in various applications, especially in the construction industry. This high-quality product is made of honeycomb composites and aluminum, offering excellent strength and durability. It is well-known for its impact resistance, heat insulation, and surface treatments such as anodizing, powder coating, and PVDF coating.This makes it an ideal choice for building curtain wall and other applications.

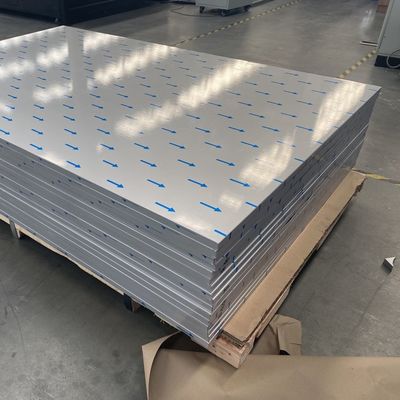

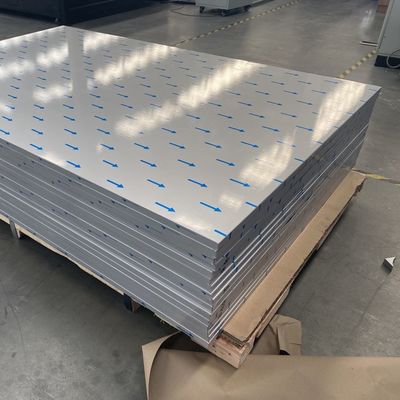

Aluminum Honeycomb Panels Packaging and Shipping:

FAQ:

Q: What is an aluminum honeycomb panel?

A: Aluminum honeycomb panels are composite panels made up of a core of aluminum honeycomb, sandwiched between two aluminum alloy skins.

Q: What are the benefits of aluminum honeycomb panels?

A: Aluminum honeycomb panels offer excellent strength-to-weight ratio, high levels of rigidity, good flatness, and superior thermal insulation and sound absorption.

Q: What are aluminum honeycomb panels used for?

A: Aluminum honeycomb panels are commonly used in the aerospace, automotive, architecture, and signage industries due to their lightweight and durable nature.

Q: What are the advantages of using aluminum honeycomb panels?

A: Aluminum honeycomb panels offer superior strength, durability, and versatility. They are also lightweight, and easy to install and maintain.

Q: Are aluminum honeycomb panels fire resistant?

A: Yes, aluminum honeycomb panels are fire resistant, and have been tested and certified to meet fire safety standards.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!