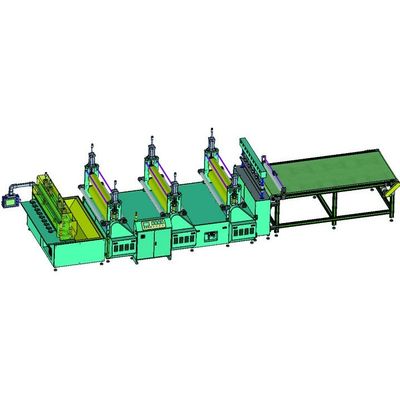

Continuous Expanding Machine Honeycomb Equipment

1. Descriptions:

1) Adhesion

Machine forms an adhesive layer on the side of honeycomb slice, puts it on working platform, adhesive

surface forward to operator, then next slice is taken and put on working platform, aligned with the first one,

pressed tightly. On the control box chose “manual mode” and press buttons in the following order: “squeeze”,

“rise pressure drum”, “pressure drum stretches out and draws back”, “pressure drum moves laterally”. In this

way, movements are finished. In the opposite order, air cylinder is back to standby mode. Adhesive is put on

the 3rd slice and all steps are made again that results in adhesion of honeycomb slices. Chose.

2) Expansion

After honeycomb slices are stick together at the previous step, material passes through carrier roller and

material squeezing roller, press “squeezing roller down”, “squeezing motor on” to deliver slice to the first

expanding roller, press “first expanding roller down”, “first expanding motor on”, slice is transferred to the

second expanding roller, press “second expanding roller down”, “second expanding motor on” that brings

whole expanding machine in motion. In accordance with expanding state, cell size, adjusted back and forth

rotor motor speed, best expanding quality can be reached.

3) Cutting

After expansion slices are forwarded to horizontal cutting area. Material is measured and cut accordingly to

programmed length. The user freely sets dimensions.

4) Transportation

After automatic cutting unit honeycomb core moved by transportation motor. Honeycomb core is pressed by

squeezing roller, core output length is measured by length measuring device, signal is sent to automatic

cutting unit previous operations, after cutting in accordance with set size honeycomb core is transported out

of line.

Extended explanations

1) Suitable for wall curtains, suspended ceiling, clean room, interior of vehicles and similar industries. Effecti-

vely reduces number of employees, increases productivity. Increases material output range, increases

production rates, reduces drum idle run, reduces employees costs.

2) Current equipment is possible to use at the continuous core production line as front-end equipment, and with

back-end rolled material complex equipment, heating equipment, cooling equipment, side-cutting machine,

measuring and cutting machine, storage manipulator and other related equipment to create ideal continuous

panel production line.

2. Specifications:

| Continuous Expanding Machine |

| Description |

Unit |

|

| Type |

|

Automatic |

| Max slice width |

mmm |

1600, 2000, 3000 |

| Max slice hight |

mm |

50mm |

| Air pressure |

MPa |

0.6 |

| Length |

mm |

customized |

| Width |

mm |

customized |

| Foil thickness |

mm |

customized |

| Cell size |

mm |

customized |

| Gross Power |

KW |

30 |

| Dimension |

mm |

10000*2000*2500 |

| Voltage |

V/Hz |

380/50 |

3. Honeycomb equipment has several advantages:

• Increase the utilization rate of core material

• Decrease idle run of expanding drums

• High efficiency

• Increase production efficiency

• Decrease employee costs

4. Applications:

• Making aluminum honeycomb core

5. Quality control:

A very technical engineering team. The general manager has worked in the Netherlands. The core technologies are introduced from the Netherlands. Others are very young and have more than 5 years of practical experience.

Strict QC team: 8 people are responsible for gluing machine honeycomb equipment of quality control of parts, processing, testing, packaging, etc.

6. Honeycomb equipment gluing machine of more pictures:

7. Company profile

Suzhou Beecore Honeycomb Materials Co.Ltd, originated from Besin (Dutch) International Group which was founded in 1957. It is the world's leading professional manufacturer of honeycomb materials. Since it' s established, the company has been committed to the research and development of honeycomb technology, from slant-porous aluminum honeycomb core, honeycomb core, honeycomb panel, to the finished product which was using honeycomb panel as the solution, such as truck body, laser TV / projection screen etc.

8. History

1957 Besin (Dutch) International Group was established and dedicated to research and development of BEECORE and BEEBOARD.

1958 Besin brought honeycomb technology into China, and Besin (Suzhou) company was established.

2002 Beecore (Guangdong) factory was established and have 10 aluminum honeycomb production lines.

2009 Suzhou Beecore Honeycomb Materials Co., Ltd was established and mainly produce aluminum honeycomb core and paper honeycomb core and other products.

2010 Beecore products are widely used for railway industry, Shanghai Expo, marine furniture etc.

2014 Beecore developed micro-porous aluminum honeycomb core and slant-porous aluminum honeycomb core, as well as honeycomb filters.

2015 Beecore added honeycomb panels production lines, specialized in super length, width, curved, and special honeycomb panels of industry field.

2016 The self-developed aluminum honeycomb equipment has been exported to Europe, America, Asia and already obtained the technology patent in China.

2017- so far Suzhou Beecore Honeycomb Materials Co., Ltd is honored as the high-technology innovation enterprise.

9. Production picture

10. FAQ

Q1. What is gluing machine honeycomb equipment usd for?

A: The gluing machine honeycomb equipment has been widely used in aluminum honeycomb core. High efficiency and low cost.

Q2. What are the advantages of honeycomb equipment?

A: Gluing machine have heating system adopts hot oil type and circulating air tunnel furnace drying system, which is safer, pollution-free, has a long service life and more uniform dying.

Over 3mm side length can achieve automatic overlapping, reduce labor and save costs.

The automatic glue supply and automatic glue regulating system is realized to reduce the number of manual glue addition, avoid solvent volatilization and prevent the instability of the product due to the large difference in viscosity of the adhesive.

Q3. What is the packaging method of honeycomb equipment?

A: Packed in plywood cases with wrapping film.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!