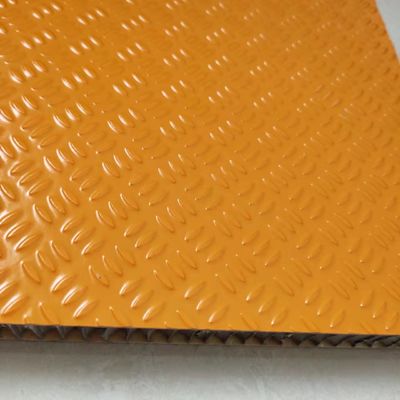

Roughness Surface And Easy To Clean FRP Aluminum Honeycomb Panel

1. Descriptions:

GRP/FRP composite panel, which structure is FRP skin + core material + FRP skin.

FRP composite panel is a high-tech, high-quality new sheet, it does not occur in the ultra-low temperature of 40 degrees brittle crack, high temperature below 100 degrees will not be deformed, and can prevent heat transfer.

FRP composite panels can replace color steel plate, aluminum, etc., and to overcome the traditional products rust, corrosion, easy to depression deformation, can not adapt to harsh environments and other shortcomings.

FRP composite board with gel coated, can be self-cleaning, anti-UV, anti-static, etc., is the most popular international truch body and van panel.

2. Specifications:

| Fiberglass honeycomb panel |

| FRP |

Skins of High Pressure Laminate |

| Thickness: from 1.0 mm to 2 mm |

| - Other thickness on request |

| - Black color or customizable |

| HONEYCOMB CORE |

3003 Aluminum Honeycomb Core or PP honeycomb core |

| Diameter (hexagonal cells): Ø 6, Ø 8, Ø 10 |

| Foil Thickness: from 40 to 80 microns |

| FRP |

Skins of High Pressure Laminate |

| Thickness: from 1.0 mm to 2 mm |

| - Other thickness on request |

| - Black color or customizable |

| Total Panel thickness |

Regular: 5mm, 8mm, 10mm, 20mm |

| -Other thickness on request |

| Dimension |

Regular: 1220*2440mm |

| -Other dimension on request |

| Specific specification of honeycomb core |

| Side length(mm) |

4, 5, 6, 7, 8, 9, 10, 12, 15, 20, 50 |

| Foil thickness(mm) |

0.04, 0.05, 0.06, 0.07, 0.08, 0.1, 0.15, 0.2 |

| Alloy |

Al3003 |

| Supply form |

Unexpanded(block, strip) or expanded(slice); |

| Technical Data Sheet |

|

Specification

|

Side length

(mm)

|

Density

(kg/m³)

|

Compression

strength (MPa)

|

L-Shear

strength (MPa)

|

W-Shear

strength (MPa)

|

| BHC3003-5-0.03 |

5 |

27 |

0.53 |

0.44 |

0.24 |

| BHC3003-5-0.04 |

5 |

31 |

0.66 |

0.53 |

0.3 |

| BHC3003-4-0.03 |

4 |

33 |

0.73 |

0.58 |

0.33 |

| BHC3003-4-0.04 |

4 |

39 |

0.98 |

0.75 |

0.43 |

| BHC3003-5-0.05 |

5 |

41 |

1.07 |

0.8 |

0.47 |

| BHC3003-3-0.03 |

3 |

44 |

1.18 |

0.89 |

0.52 |

| BHC3003-5-0.06 |

5 |

49 |

1.43 |

1.03 |

0.60 |

| BHC3003-3-0.04 |

3 |

52 |

1.6 |

1.15 |

0.67 |

| BHC3003-4-0.05 |

4 |

53 |

1.65 |

1.18 |

0.69 |

| BHC3003-4-0.06 |

4 |

61 |

2.07 |

1.48 |

0.86 |

| BHC3003-5-0.08 |

5 |

67 |

2.45 |

1.74 |

1.02 |

| BHC3003-3-0.05 |

3 |

68 |

2.50 |

1.78 |

1.04 |

| BHC3003-Beecore Aluminum Honeycomb Core, 3003 Series |

3. FRP honeycomb panel has several advantages:

• Super light and high strength, anti-fatigue

• Excellent environment adaptability and electric insulating

• Outstanding corrosion resistance and flame resistance

• Good compression and impact resistance

• Sound and heat insulation

4. Applications:

• Truck body, yacht deck, Partition, stone reinforcement, medical, automotive, industrial, sports, Kitchen countertop etc.

5. Quality control:

A very technical engineering team. The general manager has worked in the Netherlands. The core technologies are introduced from the Netherlands. Others are very young and have more than 5 years of practical experience.

Strict QC team: 8 people are responsible for Fiberglass honeycomb panel of quality control of parts, processing, testing, packaging, etc.

6. Fiberglass honeycomb panel of more pictures:

7. Company profile

Suzhou Beecore Honeycomb Materials Co.Ltd, originated from Besin (Dutch) International Group which was founded in 1957. It is the world's leading professional manufacturer of honeycomb materials. Since it' s established, the company has been committed to the research and development of honeycomb technology, from slant-porous aluminum honeycomb core, honeycomb core, honeycomb panel, to the finished product which was using honeycomb panel as the solution, such as truck body, laser TV / projection screen etc.

8. History

1957 Besin (Dutch) International Group was established and dedicated to research and development of BEECORE and BEEBOARD.

1958 Besin brought honeycomb technology into China, and Besin (Suzhou) company was established.

2002 Beecore (Guangdong) factory was established and have 10 aluminum honeycomb production lines.

2009 Suzhou Beecore Honeycomb Materials Co., Ltd was established and mainly produce aluminum honeycomb core and paper honeycomb core and other products.

2010 Beecore products are widely used for railway industry, Shanghai Expo, marine furniture etc.

2014 Beecore developed micro-porous aluminum honeycomb core and slant-porous aluminum honeycomb core, as well as honeycomb filters.

2015 Beecore added honeycomb panels production lines, specialized in super length, width, curved, and special honeycomb panels of industry field.

2016 The self-developed aluminum honeycomb equipment has been exported to Europe, America, Asia and already obtained the technology patent in China.

2017- so far Suzhou Beecore Honeycomb Materials Co., Ltd is honored as the high-technology innovation enterprise.

9. Factory show

10. FAQ

Q1. What is Fiberglass honeycomb panel usd for?

A: The Fiberglass honeycomb panel is used for industrial, truck, kitchen countertop.

Q2. What are the advantages of Fiberglass honeycomb panel?

A: Fiberglass honeycomb panel has the advantages of light weight-high strength, high surface flatness, environmental protection and no pollution.

Q3. What is the packaging method of Fiberglass honeycomb panel?

A: Fiberglass honeycomb panel of samples are packed in cardboard and bulk orders are packed in plywood cases.

12. Why choose us?

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!